Press Parts

As a result of experience gained from many repairs, we can foresee problem areas in welded component design and eliminate them at the design stage. It was a natural progression to offer such improved designs direct to our customers.

We were the first company to offer a fabricated container housing as a replacement item and our products are noted for their robust construction and reliable, accurate operation. The fabrication method offers many benefits over casting, such as greater design flexibility, later "design freeze" date and a quality control system which is continuously monitored throughout design and construction.

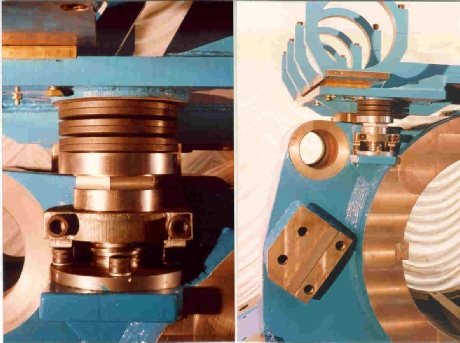

We have our own extremely strong, accurate guidance system, which is of pre-stressed design, allowing freedom of operation with a high, predictable response to any deviation from the desired position, up to predetermined limit of reactive force. Misalignment detection devices can stop the press should an serious problem occur, eliminating damage to tooling.

Our fabrication facility is approved to BS5500 for pressure vessel construction, and we have welders coded in a variety of materials.

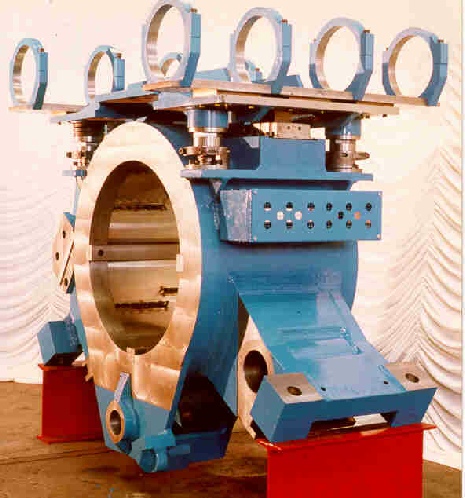

The photographs below show a container housing supplied to customer in Holland. This housing was re-designed, taking the design from a cast, 2 piece unit, to a fabricated, one piece unit, with resultant major increases in rigidity. A top column mounted guidance system was also employed.