ARNWAY - IN HOUSE CAPABILITIES

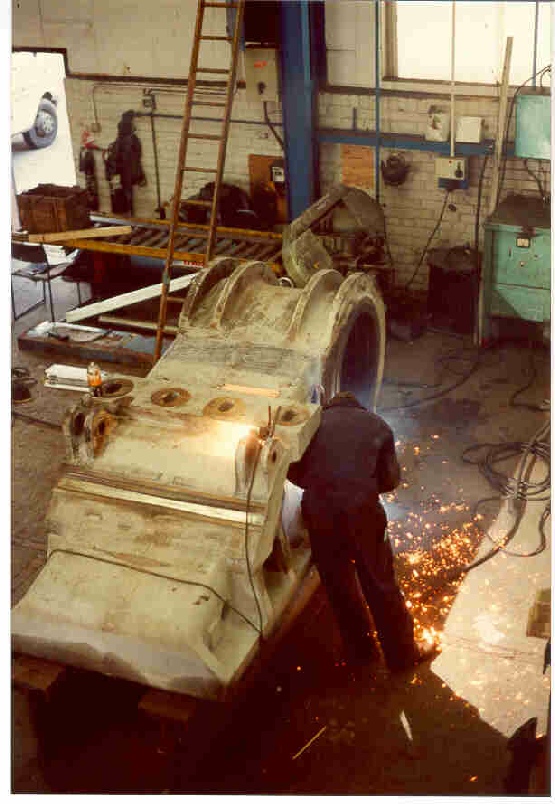

We have a fabrication facility at Burtonwood, near Warrington with overhead crane facilities and we have fabricated such items as diving decompression chambers, BS5500 Category 1 vessels. We have also designed and fabricated such items as hydraulic cylinder housings for extrusion presses, which are heavy plate forging/ fabrications.

We have a full CAD system installed, and this is a great benefit to accurate drawing and manufacturing, as we can e-mail profile drawings straight to profilers, eliminating re-drawing errors.

The fabrication shop is equipped with a 10 tonne overhead crane, complete with 3 tonne electromagnet when necessary for plate work, various welding machines with outputs up to 825A, DC and AC, and the following processes are supported:- Manual Arc (SMAW), Tungsten Inert Gas (GTAW), Metal Inert Gas (GMAW), Arc-Air gouging and metal powder surfacing. The usual complement of fabrication machinery includes site-capable 12" band saws, belt sanders etc.

For jobs over 10 tonnes, we can usually effect offloading using mobile cranes and skating inside. Using this method, we have accommodated an extrusion press main cylinder of 28 tonnes.

We have recently installed a 5" Horizontal Borer, capable of machining large jobs, in an effort to provide a more complete service to our customers.